Residential and Office Building

Projects

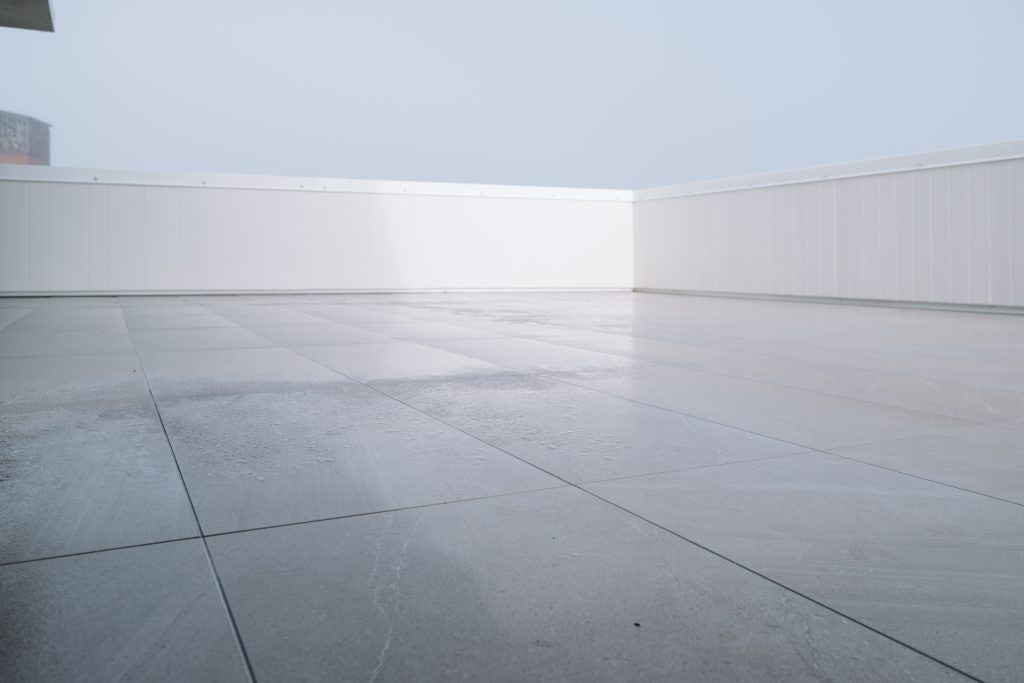

Challenging Apartment Deck Membrane Replacement No Problem with ARDEX

What began as a straightforward replacement of a 48-year old membrane turned into a more complex project, with the need to create a fall using a lightweight system that wouldn’t raise the height of the parapet.

Constructed in 1975, the impressive apartments have provided high-quality apartment living in Takapuna for almost 50 years. The apartments feature a sub penthouse suite on the second to top floor with large paved terraces with views to Lake Pupuke and the Gulf Harbour. When minor leaks were discovered in the terraces during work to the apartment below, the owners decided to replace the almost 50-year old membrane — an expectedly straightforward project, until the terrace paving was removed…

As the original membrane detailed was Butynol, Fat Parrot Architecture had previously contacted ARDEX for the project, originally with a brief for a lightweight undertile waterproofing solution. They developed a plan to use ARDEX UD150 — a thin, mesh-reinforced plastic drainage mat used directly under adhered tiled surfaces — on a thin screed bed.

“The original finish was concrete pavers approximately 40mm thick, and the drawings detailed the supporting slabs to be laid to falls,” explains Graeme Fanselow, Director, Fat Parrot Architecture. “But when the pavers were uplifted it was discovered that the slabs had in fact been laid level, with the pavers set on non-continuous beds of mortar under just their corners to create the falls — not a full mortar screed.”

At this point, a new approach was required, with the key limitations being weight — which couldn’t exceed what was installed previously, and the height of the parapet — which the homeowners did not want increased. This effectively ruled out the possibility of using a chair deck system for the new tiles, so a direct fix system on a new substrate built to the required falls was needed.

This created new challenges for the project as any new solution would need to create the fall required, while still maintaining the original height and weight. The ARDEX team worked with Fat Parrot to find a system that would resolve all issues. “ARDEX were very helpful,” says Graeme. “As things weren’t what was expected, they arranged site meetings when needed to work together and sort out the situation.”

Different build-up options were considered before they reached the final solution. “The lightweight grouts were still proving to be too heavy so we then investigated their polystyrene base — we were able to work with them on minimum thicknesses of different grouts, how thick the base could be, and whether that was going to be too much weight — we ended up right on the limit. That lightweight construction underneath allowed us to build the falls we required.”

The final build-up features a custom combination of ARDEX products. ARDEX K12 screed and ARDEX A 48 Rapid Screed unbonded have been applied above the concrete slab, with ARDEX WPM 1000 membrane installed on top. ARDEX WPM 002 liquid membrane was also used over flashing on the parapet upstand. The originally specified ARDEX UD 150 mesh-reinforced plastic drainage mat was then applied. Featuring a 6mm drainage channel, the mat allows free passage of water underneath the tiled surface to speed up drying after rainfall. ARDEX X 18 tile adhesive, ARDEX FG 8 Grout and ARDEX Grout Booster complete the installation to form a compliant build-up for the direct-fixed tiles above.

The system was installed over a 300m² area by Best Skills Limited, an applicator trained by ARDEX to ensure reliability across both specification and installation. The final system is completely unique to ARDEX and enabled them to achieve below minimal threshold requirements.

The highly bespoke system developed for the project highlights the flexibility of ARDEX’s systems, and the technical support and problem-solving expertise the ARDEX team bring to each project. “ARDEX were excellent,” says Graeme. “They gave us good technical support and have been very helpful.”

Photo Credit: David St George

More projects in Tiling

-

Challenging Apartment Deck Membrane Replacement No Problem with ARDEX

-

ARDEX Systems at Botanic Villas

-

WAI ARIKI HOT SPRINGS & SPA

Wai Ariki is a luxury spa and wellness centre based on the shores of Lake Rotorua.

-

Residential Application of ARDEX WPM 1000

WeldTec® Undertile Sheet Waterproofing Membrane

-

Airport, Newcastle

1600 sqm of natural stone laid using ARDEX adhesives

-

Rydges Hotel Wellington Airport

A Fantastic Addition to Wellington's Accommodation Scene

-

SO/Auckland Hotel

SystemARDEX specified for a luxurious, high-end hotel complex

-

Wynyard Central Pavilions

SystemARDEX specified for a high end apartment project

-

Fiji Marriott Resort Momi Bay

New Luxury Resort Receives the SystemARDEX Treatment

-

The British Museum, UK

ARDEX provide The British Museum with a floor built to withstand its ever increasing popularity

-

London 2012 Aquatic Centre

866,000 tiles were fixed in the London Aquatics Centre

-

2014 Commonwealth Games Swimming Pool, Glasgow

Tollcross International Swimming Centre

-

Elevate Apartments, Wellington

-

MERCEDES BENZ AUTOHAUS, NEWSTEAD

ARDEX System Specified for Unique 32,000m² Auto Dealership

-

Water Playground – Elizabeth Quay, Perth

Complete ARDEX system chosen as part of Elizabeth Quay Development

-

The Pool of Reflection, Sydney

Complete ARDEX system used for restoration works at Hyde Park memorial

-

Opera House Western Foyer, Sydney

ARDEX adhesive, grout and primer used at Sydney Opera House

-

Westfield Miranda, Sydney

ARDEX specification chosen for project requiring quick turnaround

-

The Emporium, Melbourne

21,000 sqm of tiling completed using ARDEX adhesive and grout

-

Lure Apartments, Nelson Bay

ARDEX sound proofing system used in new prestigious development

-

Elevation Apartments, Perth

ARDEX System used in prestigious development right in the heart of Perth’s CBD

-

215 Adelaide Street, Brisbane

Refurbishment of office tower complex

-

Q1 Surfers Paradise, Brisbane

ARDEX tile adhesives, soundproofing requirements, grouts and floor leveling were used in this residential tower

-

The Vibe Hotel, Canberra

5000 sq. metres of ARDEX tile adhesive was used for The Vibe Hotel